Patented Product

Smart Valve Actuator

Redefining Industrial Control with Intelligence

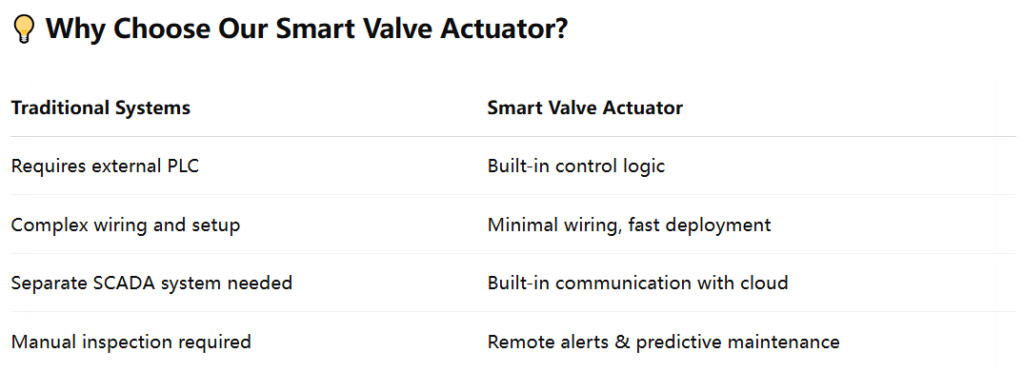

As industrial automation and smart manufacturing evolve, we proudly present our patented Smart Valve Actuator, a next-generation product that integrates PLC functionality and gateway communication into a compact, intelligent unit. This innovative design eliminates the need for external control systems, significantly reducing wiring complexity and total investment, and is ideal for applications in gas, water treatment, chemical, and power industries.

Equipped with an embedded intelligent control unit, our actuator performs signal processing and logic operations independently to precisely control valve position — saving up to 50% in system costs compared to traditional PLC-based setups.

Seamlessly integrates with standard industrial signals:

– 4–20 mA analog input (e.g., pressure, temperature, flow rate)

– Digital I/O for alarms, fault feedback, and interlock signals

– Modbus RTU support to interface with smart meters, gas leak detectors, temperature/humidity sensors, etc.

– Wired communication: RS485, Ethernet port, compatible with PLC or SCADA systems

– Wireless access: Mobile app, cloud platform, and 4G/5G connectivity for real-time remote control and monitoring

– Fully supports cloud data upload for remote diagnostics, alerts, and predictive maintenance

– Intelligent control for flow, pressure, and temperature in process industries

– Unattended operation at gas regulating stations, heating stations, and water booster stations

– Water treatment plants and energy management centers

– Legacy system upgrades with intelligent retrofitting for energy savings

– Wireless access: Mobile app, cloud platform, and 4G/5G connectivity for **real-time remote control and monitoring**

– Fully supports cloud data upload for **remote diagnostics, alerts, and predictive maintenance**

– Intelligent control for flow, pressure, and temperature in process industries

– Unattended operation at gas regulating stations, heating stations, and water booster stations

– Water treatment plants and energy management centers

– Legacy system upgrades with intelligent retrofitting for energy savings